What significant advantages does the high uniformity of machine vision light source bring to the inspection of complex surfaces?

Release Time : 2026-01-05

In today's rapidly developing industrial automation and intelligent manufacturing, machine vision light source systems have become a core technology for product quality control, precision measurement, and intelligent sorting. As the "eye of the eye" of the machine vision light source, the light source not only determines the image clarity but also directly affects the accuracy and stability of the algorithm's recognition. Especially when dealing with curved metal surfaces, transparent materials, highly reflective parts, or workpieces with complex textures, machine vision light sources demonstrate irreplaceable key value.

1. High Uniform Illumination: Eliminating Interference and Restoring True Surface Features

Complex surfaces generally exhibit characteristics such as variable reflection directions, large local differences in brightness, and strong microstructure scattering. Using ordinary non-uniform light sources easily creates highlights, shadow areas, vignetting effects, or brightness gradients in the image. These optical artifacts can severely mask real defects and even be misjudged as anomalies.

High uniformity light sources, through optimized LED arrangement and the use of diffuser plates, light guide plates, or integrating sphere structures, control the illuminance difference in the illuminated area within ±5%. This "shadowless, glare-free, and gradient-free" lighting environment maximizes the reproduction of the true geometric and textural information of an object's surface. For example, when inspecting the metal frame of a mobile phone, uniform backlighting or low-angle diffused light allows minute scratches to appear as clear linear dark lines, rather than being obscured by strong reflections; when inspecting leather interiors in automobiles, uniform front lighting highlights the consistency of embossing, avoiding the loss of detail due to localized overexposure.

2. Improved Contrast and Detectability of Minor Defects

The core of machine vision light source inspection lies in "feature contrast." Highly uniform illumination significantly improves the grayscale or color difference between defects and normal areas by stabilizing background brightness. Taking PCB board solder joint inspection as an example, if the light source is uneven, the difference in reflective intensity of solder joints at different locations on the same board may be far greater than the defect itself, leading to missed detections. However, by using highly uniform coaxial light or dome light sources, all solder joints exhibit consistent brightness, allowing the algorithm to accurately detect minute defects such as cold solder joints, insufficient solder, or misalignment.

In the detection of transparent or semi-transparent objects, uniform backlighting combined with polarization technology can reveal internal bubbles, impurities, or uneven wall thickness with high contrast. Experiments show that, under the same camera and algorithm conditions, using highly uniform lighting can improve the detection rate of micron-level defects by more than 30% and reduce the false alarm rate by 50%.

3. Enhanced Algorithm Robustness and Reduced Dependence on Post-Processing

Many vision systems rely on complex image preprocessing to compensate for uneven illumination. This not only increases the computational burden but may also introduce new distortions. Highly uniform lighting provides "clean" raw images from the source, significantly simplifying subsequent processing.

For example, in deep learning training, if the training set images are severely affected by illumination, the model needs to learn a large number of irrelevant variables, resulting in decreased generalization ability. However, data acquired based on highly uniform illumination focuses more on the target itself, leading to faster model convergence and higher accuracy. Furthermore, in real-time online detection, stable illumination means that thresholds, template matching parameters, etc., can be fixed for a long time without frequent adjustments, greatly improving the long-term reliability of the system.

High-uniformity light sources are not a single product, but a solution encompassing multiple technological approaches:

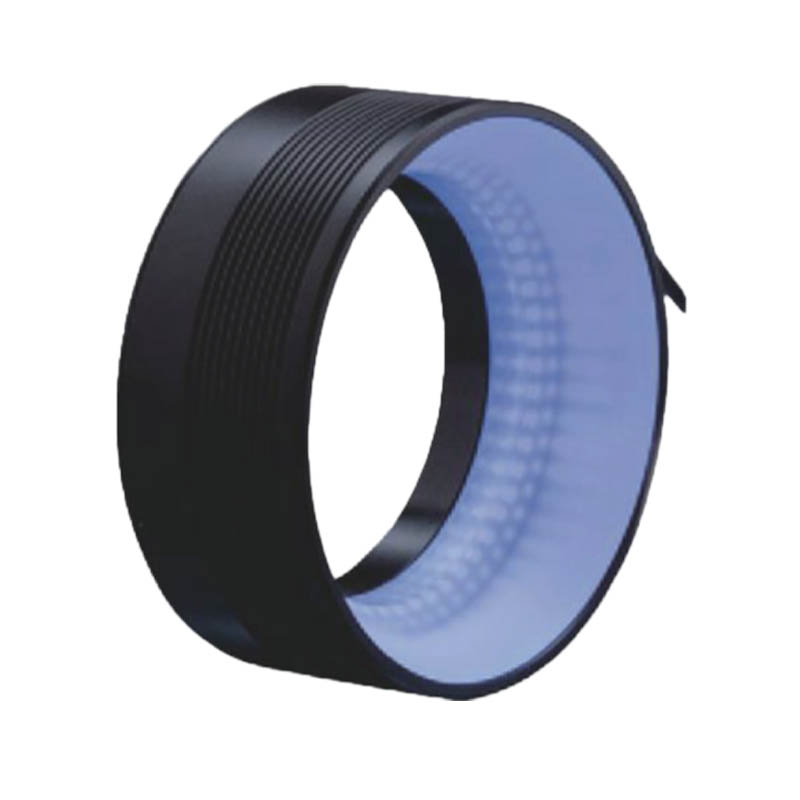

Dome Light Source: Achieves near-ideal non-directional uniform illumination through multiple diffuse reflections from the inner wall, specifically designed for highly reflective curved surfaces;

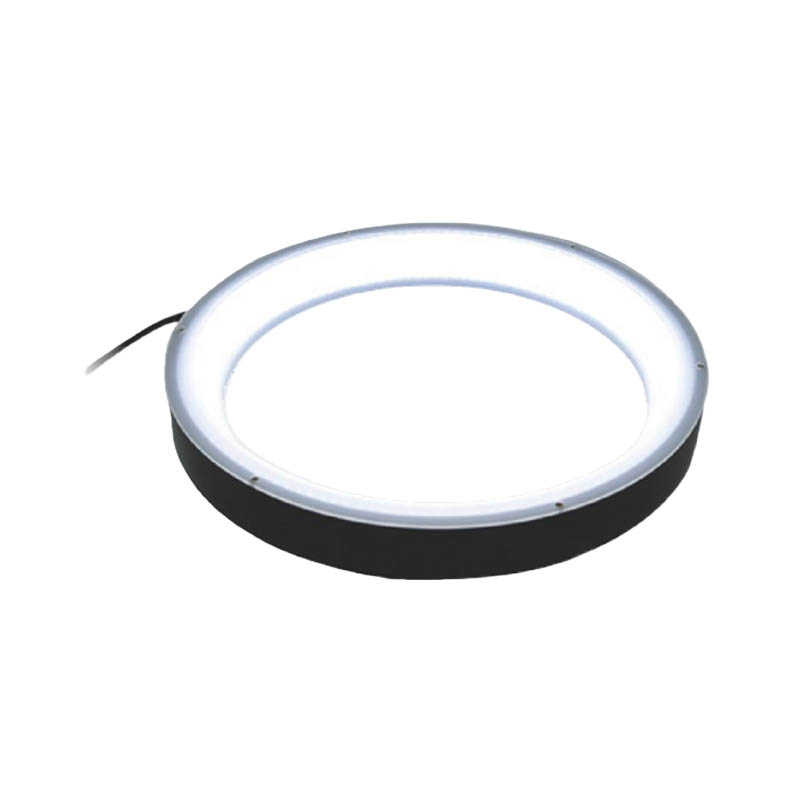

Backlight Source: Provides extremely uniform contour illumination for high-precision dimensional measurement and defect detection of transparent objects;

High-uniformity strip/area light source: Combines diffusion film and uniform light design, suitable for large-area flat workpieces;

Programmable zoned light source: Dynamically adjusts local brightness while maintaining overall uniformity, suitable for composite material surfaces.

In fields with stringent requirements for inspection accuracy, such as semiconductor packaging, new energy battery electrodes, medical devices, and consumer electronics, high-uniformity light sources have become standard. For example, lithium battery tab welding inspection requires the identification of 0.1mm-level weld slag, and only highly uniform, low-angle light can avoid interference from metal reflections; in mobile phone camera lens assembly, the detection of dust particles relies entirely on enhanced scattering under uniform dark-field illumination.

5. Dual Guarantee of Economic Benefits and Long-Term Stability

Although the initial cost of high-uniformity light sources is slightly higher, their comprehensive benefits are significant:

Reduced scrap rates and rework costs due to misjudgments;

Extended maintenance-free cycles for vision systems;

Support for higher production line speeds;

Reduce reliance on operators' lighting skills, achieving "plug and play" functionality.

Meanwhile, modern high-uniformity light sources generally employ high-stability LED chips and constant current drives, with a lifespan exceeding 50,000 hours and light decay of less than 5%, ensuring consistent inspection results year after year.

In the process of machine vision light sources moving from "seeing" to "seeing accurately and steadily," high-uniformity light emission is no longer an added bonus, but a cornerstone of complex surface inspection. Like a silent artist, it reveals the most subtle truths with the most understated light. In the future, with the development of technologies such as Mini-LED uniform lighting and AI adaptive lighting, high-uniformity light sources will further break through physical limits, illuminating a clearer and more reliable visual eye for intelligent manufacturing.

1. High Uniform Illumination: Eliminating Interference and Restoring True Surface Features

Complex surfaces generally exhibit characteristics such as variable reflection directions, large local differences in brightness, and strong microstructure scattering. Using ordinary non-uniform light sources easily creates highlights, shadow areas, vignetting effects, or brightness gradients in the image. These optical artifacts can severely mask real defects and even be misjudged as anomalies.

High uniformity light sources, through optimized LED arrangement and the use of diffuser plates, light guide plates, or integrating sphere structures, control the illuminance difference in the illuminated area within ±5%. This "shadowless, glare-free, and gradient-free" lighting environment maximizes the reproduction of the true geometric and textural information of an object's surface. For example, when inspecting the metal frame of a mobile phone, uniform backlighting or low-angle diffused light allows minute scratches to appear as clear linear dark lines, rather than being obscured by strong reflections; when inspecting leather interiors in automobiles, uniform front lighting highlights the consistency of embossing, avoiding the loss of detail due to localized overexposure.

2. Improved Contrast and Detectability of Minor Defects

The core of machine vision light source inspection lies in "feature contrast." Highly uniform illumination significantly improves the grayscale or color difference between defects and normal areas by stabilizing background brightness. Taking PCB board solder joint inspection as an example, if the light source is uneven, the difference in reflective intensity of solder joints at different locations on the same board may be far greater than the defect itself, leading to missed detections. However, by using highly uniform coaxial light or dome light sources, all solder joints exhibit consistent brightness, allowing the algorithm to accurately detect minute defects such as cold solder joints, insufficient solder, or misalignment.

In the detection of transparent or semi-transparent objects, uniform backlighting combined with polarization technology can reveal internal bubbles, impurities, or uneven wall thickness with high contrast. Experiments show that, under the same camera and algorithm conditions, using highly uniform lighting can improve the detection rate of micron-level defects by more than 30% and reduce the false alarm rate by 50%.

3. Enhanced Algorithm Robustness and Reduced Dependence on Post-Processing

Many vision systems rely on complex image preprocessing to compensate for uneven illumination. This not only increases the computational burden but may also introduce new distortions. Highly uniform lighting provides "clean" raw images from the source, significantly simplifying subsequent processing.

For example, in deep learning training, if the training set images are severely affected by illumination, the model needs to learn a large number of irrelevant variables, resulting in decreased generalization ability. However, data acquired based on highly uniform illumination focuses more on the target itself, leading to faster model convergence and higher accuracy. Furthermore, in real-time online detection, stable illumination means that thresholds, template matching parameters, etc., can be fixed for a long time without frequent adjustments, greatly improving the long-term reliability of the system.

High-uniformity light sources are not a single product, but a solution encompassing multiple technological approaches:

Dome Light Source: Achieves near-ideal non-directional uniform illumination through multiple diffuse reflections from the inner wall, specifically designed for highly reflective curved surfaces;

Backlight Source: Provides extremely uniform contour illumination for high-precision dimensional measurement and defect detection of transparent objects;

High-uniformity strip/area light source: Combines diffusion film and uniform light design, suitable for large-area flat workpieces;

Programmable zoned light source: Dynamically adjusts local brightness while maintaining overall uniformity, suitable for composite material surfaces.

In fields with stringent requirements for inspection accuracy, such as semiconductor packaging, new energy battery electrodes, medical devices, and consumer electronics, high-uniformity light sources have become standard. For example, lithium battery tab welding inspection requires the identification of 0.1mm-level weld slag, and only highly uniform, low-angle light can avoid interference from metal reflections; in mobile phone camera lens assembly, the detection of dust particles relies entirely on enhanced scattering under uniform dark-field illumination.

5. Dual Guarantee of Economic Benefits and Long-Term Stability

Although the initial cost of high-uniformity light sources is slightly higher, their comprehensive benefits are significant:

Reduced scrap rates and rework costs due to misjudgments;

Extended maintenance-free cycles for vision systems;

Support for higher production line speeds;

Reduce reliance on operators' lighting skills, achieving "plug and play" functionality.

Meanwhile, modern high-uniformity light sources generally employ high-stability LED chips and constant current drives, with a lifespan exceeding 50,000 hours and light decay of less than 5%, ensuring consistent inspection results year after year.

In the process of machine vision light sources moving from "seeing" to "seeing accurately and steadily," high-uniformity light emission is no longer an added bonus, but a cornerstone of complex surface inspection. Like a silent artist, it reveals the most subtle truths with the most understated light. In the future, with the development of technologies such as Mini-LED uniform lighting and AI adaptive lighting, high-uniformity light sources will further break through physical limits, illuminating a clearer and more reliable visual eye for intelligent manufacturing.